Sale!

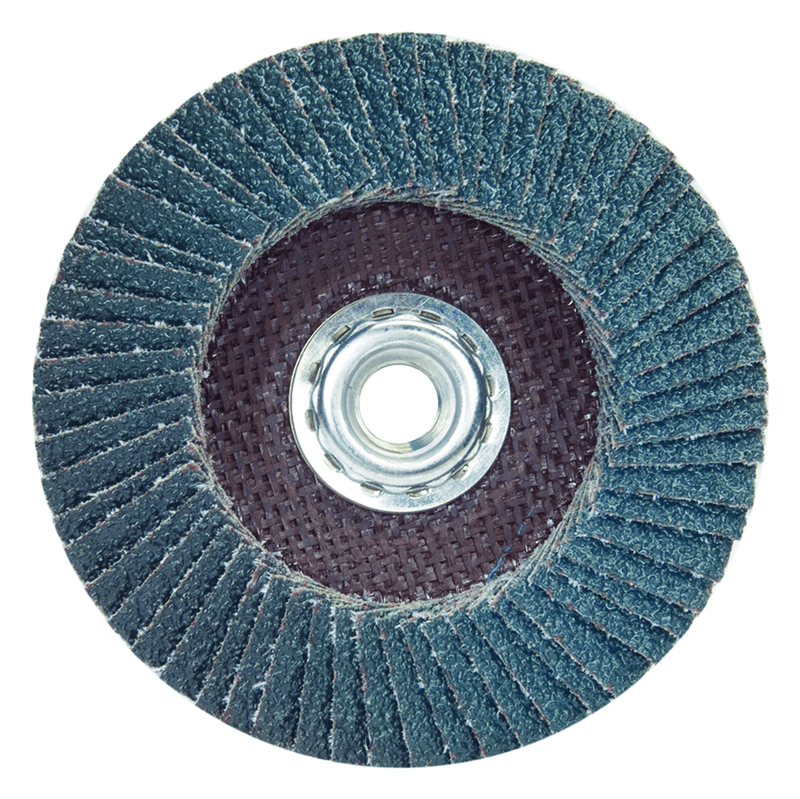

Merit MM5919994 4-1/2 x 5/8 – 11" Metal Fiberglass Conical Flap Disc Type 29 P40 Grit R828 Zirconia Alumina Supply

Original price was: $7.87.$3.15Current price is: $3.15.

Description

Merit MM5919994 4-1/2 x 5/8 – 11" Metal Fiberglass Conical Flap Disc Type 29 P40 Grit R828 Zirconia Alumina

Short Description

Norton Abrasives 31191506 4-1/2 x 5/8 – 11″ Metal Fiberglass Conical Flap Disc Type 29 P40 Grit R828 Zirconia Alumina

Full Description

| Type | Coated Flap Discs,Discs | Trade Name | METAL |

| Abrasive Material | Zirconia Alumina | Wheel Type | Type 29 |

| Diameter | 4.5″ | Backing Material | X-wt. Cotton |

| Arbor Hole | 5/8″ – 11 | Density | Standard Density |

| Grit | P40 Grit | Standard Pack | 10 |

| Grade | Extra Coarse Grit | Style | Tapered on fiberglass pad |

| Maximum RPM | 13,300 |

• Fiberglass Conical Flap Disc,Flap Discs • Bevel, blend, deburr and remove stock with high speed and efficiency using Metal R828 coarse grit arbor thread fiberglass conical flap discs. Engineered with angled polyester/cotton flaps, a high surface area and a durable zirconia grain, these long-life, type-29 flap discs work great on edges and contoured surfaces and efficiently cut titanium, super alloys, cast iron, and soft-carbon, and 300 and 400 series stainless steels. Featuring the most popular backing plate configuration on the market, these fiberglass/resin-backed flap discs are strong and lightweight, and they also absorb vibration, enhancing operator comfort. • Type 29 conical flap discs with durable zirconia grain provide good cut and life for all-purpose work • Angled, polyester/cotton flaps provide greater surface contact and are the best choice when speed of job completion and stock removal are primary considerations; may be used on contour and edge work • Their fiberglass/resin backing plates are the most popular plate configuration due to high strength, light weight, ability to absorb vibration, and operator comfort • Good choice for coarse grit blending, deburring, and stock removal • Coarse 40 grit for stock removal, beveling and edge chamfering